The company is committed to the research and development of software, hardware and supporting equipment of nitrogen oxide sensor and exhaust temperature sensor and assembly. The existing plant covers an area of more than 1000 square meters, and the employees are industry elites. They have been engaged in the post-treatment industry for many years, and have formed a high standard, high stability and high-quality technical team, which has improved the core competitiveness and technical research level of the company.

After years of technical exploration and summary, our company has accumulated rich project experience, perfectly combined the principle and characteristics of nitrogen oxide sensor and exhaust temperature sensor with computer technology, communication technology and embedded technology, and flexibly configured the product design, detection, production and calibration in the way of “unified design and platform integration”, so as to create a leading first-class solution.

At present, the company has many generations of independently developed nitrogen oxide sensor control board. The company’s R & D policy implements the idea of mutual progress between software and hardware, and optimizes and upgrades software on a stable hardware platform; When the software environment is mature, do the hardware design optimization. It ensures the stability of products used by customers and smoothly realizes the upgrading of products.

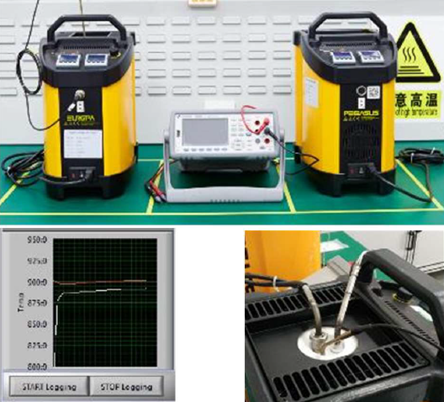

Our company not only realizes independent research and development on products, but also realizes independent design and development on supporting tools. In order to ensure the consistency of the equipment and the automatic calibration of the aging equipment, our company has independently developed and manufactured the equipment, so as to ensure the consistency of the equipment. The calibration equipment of our company uses Horiba flowmeter to ensure the stability of gas distribution atmosphere, so that the retest of the same product can achieve the same performance, and the calibration deviation of batch products is within 2%, so as to achieve the industry-leading level.

The company has a stable supply channel of production materials mainly through the cooperation of domestic stable suppliers. At present, the company plans to have an annual production capacity of 50-60k nitrogen oxide sensor assemblies. The company plans to invest in equipment, technical transformation, production management and other measures to improve production capacity and production efficiency. An annual output of 100k nitrogen oxide sensor assembly lines will be realized in 2023.

Quality Control

3.1 Clean workshop

Our workshop adopts dust-free management

● Be admitted to enter after change shoes or use a shoe cover.

● Staffs change uniforms.

● Clear the dust through air shower.

3.2 IATF 16949 management system

Workshop is managed strictly according to IATF 16949 standard.

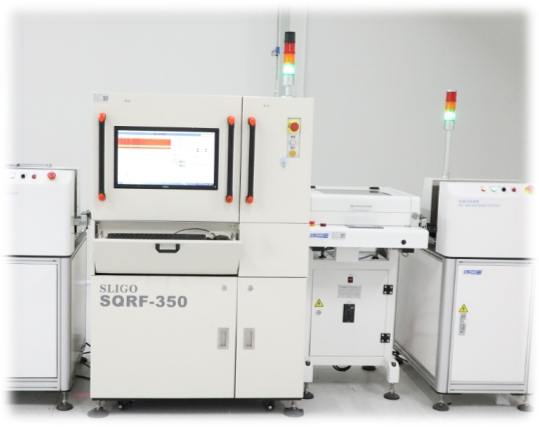

3.3 Automation Equipment

Over 80% Automation Equipment can effectively defects which are easily caused by human operation are avoided.

3.4 Process control & Test

● Traceability system of the entire workflow, From raw materials to finished products.

Cover each part and each step of the process, help us better troubleshoot problems and improve production processes.

● High temperature and aging test to ensure product durability and stable performance .

● 100% test and calibration before Delivery.

3.5 Data

● Scale of production:more than 50,000 Pcs Monthly output;

● Product Accuracy rate: ± 10% ± 10ppm;

● Product Lifespan: 2,000 hours Or 200,000 km;

● Warranty: 12 Months.

● ESC and ETC Test reports